solutions

Delivering Peak Panel Performance

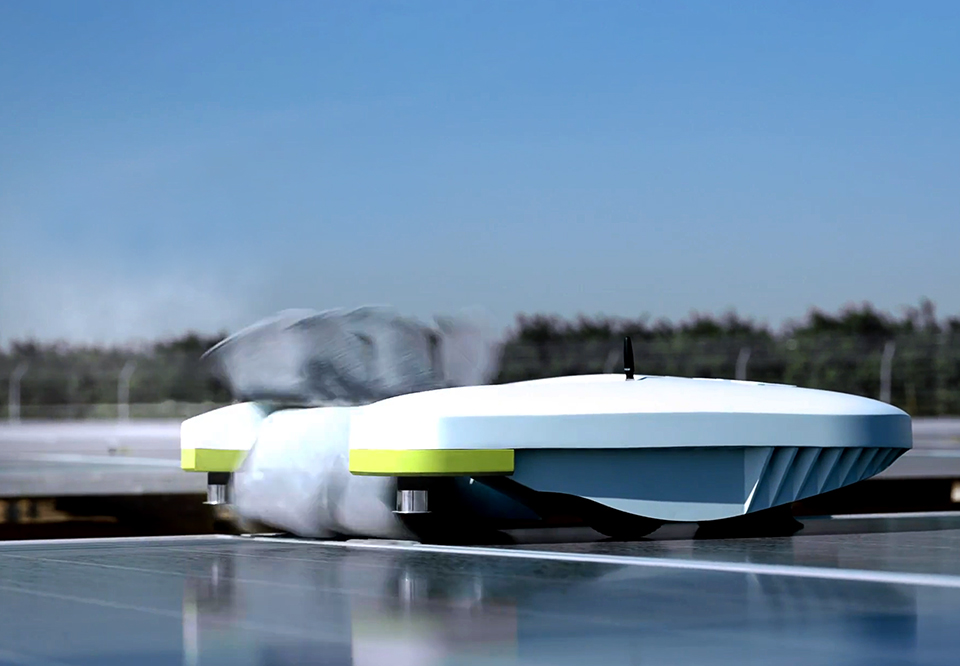

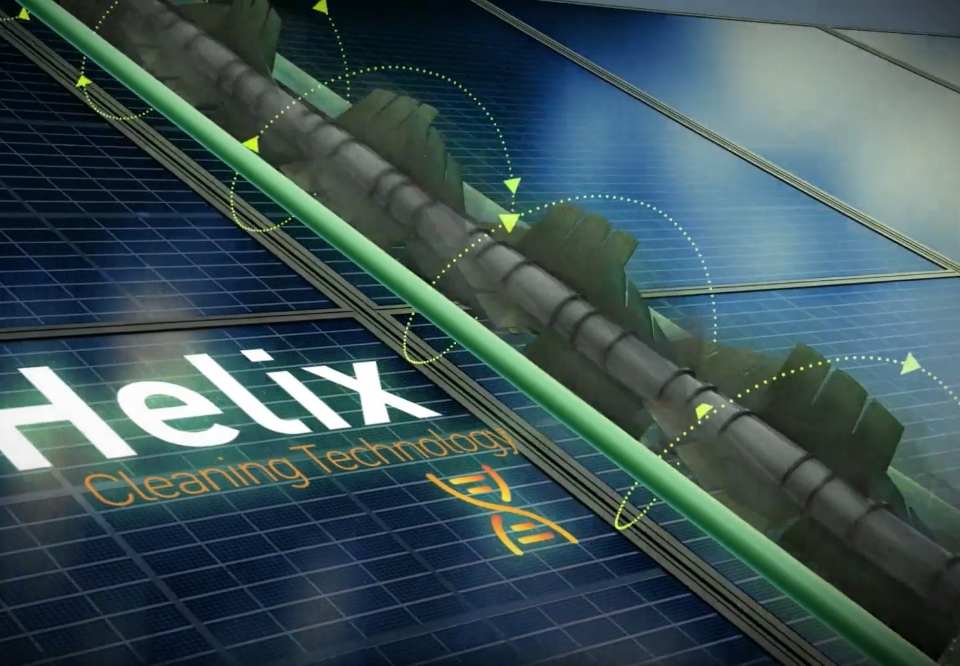

At the forefront of automation, Ecoppia offers a suite of robust, reliable, and field proven robotic solutions that optimize performance while dramatically reducing PV sites’ O&M costs

Download the T4 Datasheet

Download the E4-E4+ Datasheet

Download the H4 Datasheet

SERVICES

The Ecoppia Professional Services team supports our customers during the entire lifetime of the project. We offer an all-inclusive 25-year warranty for our installations, and deliver a wide range of services starting from early stage of design:

- PLANNING

- COMISSIONING

- MAINTENANCE

- MONITORING AND ANALYSIS

The Ecoppia Professional Services team supports our customers during the entire lifetime of the project. We offer an all-inclusive 25-year warranty for our installations, and deliver a wide range of services starting from early stage of design:

Optimizing site design to minimize investment

Tight interaction with developers, EPC’s and structure provider’s teams

Configurations and installation of all robots on site

SCADA training for system monitoring and service analysis

Final QA cycle on site

Pre-scheduled maintenance windows and advanced predictive maintenance ensure constant availability

Monitoring of system components

Collection and evaluation of forecasted and real time weather

Constant service enhancement using sophisticated algorithms

Analytics via dedicated interface